A well-designed racking system can transform not just the physical landscape of a warehouse, but the lives of the workers who navigate its aisles daily, the efficiency of operations that depend upon it, and the economic trajectory of businesses that invest wisely in storage infrastructure. Behind every successful logistics operation lies a carefully orchestrated network of steel and strategy, where human ingenuity meets industrial necessity. The stories these structures tell extend far beyond mere storage; they speak to our evolving relationship with space, efficiency, and the relentless pursuit of optimisation in an increasingly connected world.

The Human Architecture of Industrial Storage

Within the towering corridors of modern warehouses, warehouse racking systems serve as the silent backbone of global commerce. Each vertical structure represents countless decisions made by engineers, warehouse managers, and workers who understand that storage is never merely about putting things away. It is about creating pathways for human movement, establishing rhythms of work, and building systems that can adapt to the unpredictable demands of modern supply chains.

The evolution of these systems mirrors broader changes in how we work and live. Where once warehouse workers might have climbed ladders and manually sorted through chaotic piles of inventory, today’s storage racking systems create organised vertical cities where forklifts glide through predetermined channels and automated systems communicate with human operators in real time.

Navigating the Landscape of Storage Solutions

Industrial racking systems come in configurations as varied as the businesses they serve, each designed to address specific challenges while accommodating the human element that remains central to warehouse operations. The choice between selective, drive-in, push-back, or cantilever systems often reflects not just storage requirements, but the culture and capabilities of the workforce that will use them daily.

Consider the fundamental types that shape modern warehouse environments:

• Selective racking: Offering individual access to every pallet position, supporting diverse inventory needs

• Drive-in systems: Maximising density through deep storage lanes, requiring skilled operators

• Push back configurations: Enabling FIFO rotation whilst maintaining high storage density

• Cantilever structures: Accommodating irregular loads that standard systems cannot handle

• Mobile racking: Reducing aisle requirements through mechanically assisted movement

Each variation tells a story of compromise and optimisation, of balancing accessibility against density, speed against safety, and immediate needs against long-term flexibility.

Singapore’s Strategic Vision for Warehouse Innovation

In Singapore’s compact urban landscape, where every square metre carries premium value, the approach to storage infrastructure reflects broader national strategies for economic efficiency. As one logistics industry observer noted, “Singapore’s racking system implementations demonstrate how space-constrained economies can leverage intelligent design to maintain competitive advantage in global trade.” This perspective reveals how technical decisions about storage systems connect to larger questions of national economic strategy and urban planning.

The city state’s embrace of sophisticated pallet racking systems reflects a deeper understanding that in a globally connected economy, the efficiency of storage infrastructure directly impacts competitiveness. Here, the choice of racking solution becomes an act of strategic planning, where warehouse operators must balance immediate operational needs against long-term adaptability in rapidly changing markets.

The Economics of Vertical Efficiency

Behind every racking system lies a complex calculus of cost, efficiency, and human productivity. The initial investment in quality storage infrastructure often represents a leap of faith for businesses, particularly smaller operations where every capital expenditure must demonstrate clear returns. Yet the mathematics of vertical storage reveal compelling truths about space utilisation and operational efficiency.

Modern racking solutions can increase storage capacity by 30 to 60 per cent within existing footprints, transforming warehouse economics in ways that extend far beyond simple space savings. Reduced travel time for workers, improved inventory accuracy, enhanced safety protocols, and better integration with automated systems all contribute to operational improvements that compound over time.

Implementation Challenges and Human Considerations

The installation of new warehouse racking systems inevitably disrupts established rhythms of work, requiring careful attention to the human dimension of technological change. Workers who have developed expertise in navigating existing layouts must adapt to new configurations, learn updated safety protocols, and adjust to different operational workflows.

Successful implementation requires understanding that racking systems exist within human ecosystems. Training programs, safety briefings, and gradual transition periods acknowledge that even the most sophisticated storage infrastructure depends upon workers who understand its capabilities and limitations. The best systems support human decision-making rather than attempting to replace it entirely.

Safety Protocols and Regulatory Frameworks

The vertical nature of modern storage creates inherent risks that demand comprehensive safety strategies. Racking solutions must comply with rigorous engineering standards whilst accommodating the reality that warehouses are dynamic environments where human error, equipment malfunction, and unexpected circumstances can create dangerous situations.

Regular inspections, load limit monitoring, impact damage assessment, and seismic safety considerations all form part of responsible racking system management. These protocols reflect hard learned lessons from industrial accidents and regulatory evolution, embodying a commitment to protecting workers whilst maintaining operational efficiency.

Future Trajectories in Storage Technology

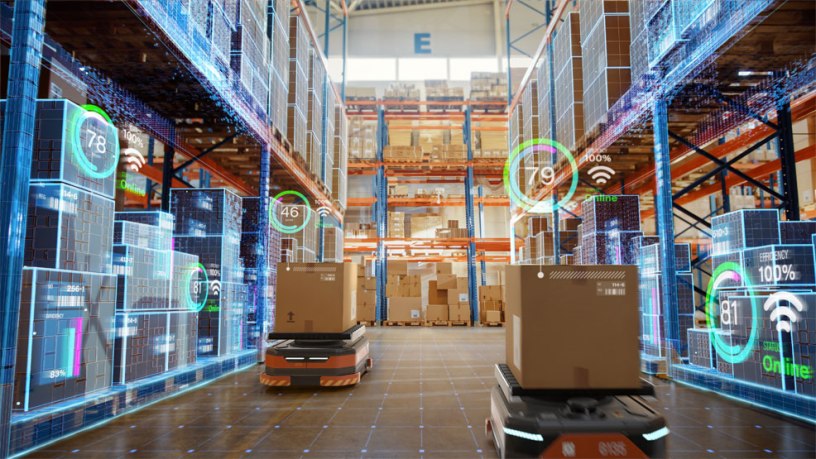

The integration of digital technologies with traditional storage infrastructure promises to reshape how we think about warehouse racking systems. Sensors embedded within structures monitor load distribution and structural integrity in real time. Automated guided vehicles navigate optimised pathways between racking units. Warehouse management systems coordinate human and mechanical activities with increasing sophistication.

Yet these technological advances build upon fundamental principles of organisation, safety, and efficiency that remain grounded in human needs and capabilities. The most advanced automated systems still require human oversight, maintenance, and decision-making at critical junctions.

The future of warehouse storage lies not in replacing human judgment with mechanical precision, but in creating synergies between technological capability and human expertise. As global supply chains become increasingly complex and demanding, the businesses that thrive will be those that recognise storage infrastructure as a strategic asset requiring thoughtful investment in both technology and people, supported by carefully selected racking system solutions that serve both operational efficiency and human dignity.